Introduction to 3D Printing in Medical Device Prototyping

Welcome to the cutting-edge world of 3D printing in medical device prototyping! Imagine being able to bring your innovative ideas for medical devices to life with precision and speed. With the help of professional 3D printing services, turning concepts into tangible prototypes has never been easier. Let’s dive into how you can choose the right 3D printing service for your next groundbreaking project in medical device development.

Benefits of Using a 3D Printing Service

When it comes to medical device prototyping, utilizing a 3D printing service offers numerous benefits. One of the key advantages is the ability to quickly iterate and customize designs without incurring high costs or long lead times. This agility allows for faster development cycles and more efficient testing processes.

Furthermore, 3D printing services provide access to a wide range of materials suitable for medical applications, ensuring that prototypes can closely mimic the properties of final products. Whether you need biocompatible materials for implantable devices or durable options for surgical tools, there is a material available to meet your specific requirements.

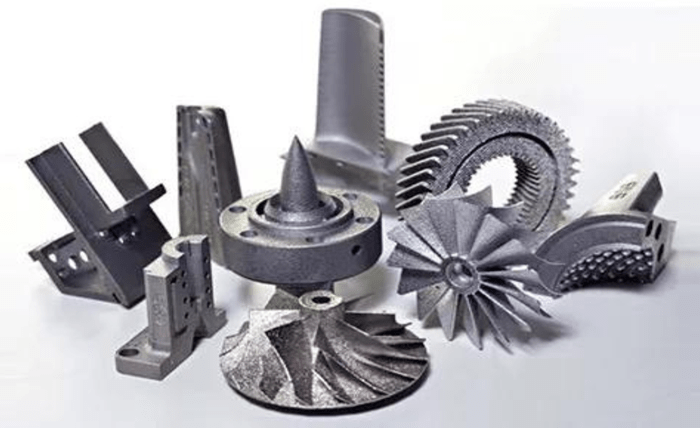

Another benefit of using a 3D printing service is the opportunity to leverage advanced technologies like additive manufacturing techniques. These cutting-edge methods enable intricate designs and complex geometries that may not be achievable through traditional manufacturing processes.

Partnering with a reputable 3D printing service can significantly enhance the efficiency and effectiveness of your medical device prototyping initiatives.

Factors to Consider When Choosing a 3D Printing Service

When it comes to choosing a 3D printing service for your medical device prototyping needs, there are several important factors to consider. First and foremost, you should look at the experience and expertise of the 3D printing service provider. Make sure they have a proven track record in producing high-quality medical device prototypes.

Another crucial factor is the range of materials offered by the 3D printing service. Different materials have varying properties that can impact the functionality and durability of your prototype. It’s essential to choose a service that offers a variety of materials suitable for medical applications.

Cost is also an important consideration when selecting a 3D printing service. While you don’t want to compromise on quality, it’s still necessary to find a provider that offers competitive pricing within your budget constraints.

Moreover, turnaround time plays a significant role in product development timelines. Selecting a 3D printing service with quick turnaround times can help speed up the prototyping process and bring your medical device to market faster.

Communication is key when working with a 3D printing service provider. Ensure they are responsive, open to feedback, and willing to collaborate closely with you throughout the prototyping process for successful outcomes.

Types of Materials Used in Medical Device Prototyping

When it comes to medical device prototyping, the choice of materials is crucial for functionality and safety.

One common material used is ABS plastic, known for its durability and impact resistance. It’s a popular choice for prototypes due to its affordability.

For more intricate designs requiring high precision, Nylon is often preferred. This material offers strength while allowing for fine details in the prototype.

Another commonly used material is PLA, a biodegradable thermoplastic. It’s environmentally friendly and suitable for early-stage prototypes.

For prototypes that need to withstand high temperatures or harsh environments, materials like Polycarbonate are ideal. They offer heat resistance and toughness.

Silicone rubber is often chosen for medical devices needing flexibility and hypoallergenic properties. It’s perfect for creating soft components in prototypes.

Case Studies: Successful Medical Device Prototypes Using 3D Printing Services

In the world of medical device prototyping, 3D printing services have revolutionized the way new innovations come to life. Let’s take a look at some real-life case studies where this technology has made a significant impact.

One notable example is the development of a custom prosthetic limb using 3D printing. By working with a specialized service provider, designers were able to create a personalized and functional prototype that perfectly fit the patient’s needs.

Another success story involves the production of intricate surgical tools through additive manufacturing. These tools were tailored to specific surgical procedures, showcasing how 3D printing allows for precise customization in healthcare settings.

Furthermore, researchers have utilized 3D printing services to produce accurate anatomical models for pre-surgical planning. This level of detail enhances surgeons’ ability to visualize complex procedures and ultimately improves patient outcomes.

Tips for Communicating with Your Chosen 3D Printing

Effective communication with your chosen 3D printing service is key to ensuring the success of your medical device prototyping project. Be clear and specific about your requirements, deadlines, and expectations from the beginning. Provide detailed feedback on prototypes to help iterate and improve designs efficiently. Keep an open line of communication for any questions or concerns that may arise during the process.

By following these tips and considering the factors mentioned earlier when choosing a 3D printing service for medical device prototyping, you can set yourself up for a successful collaboration that brings your innovative ideas to life. Embrace the opportunities that advanced technology like 3D printing offers in revolutionizing the healthcare industry through rapid prototyping and customization tailored to specific patient needs.