Cryogenic shock testing of small pressure vessels has determined the reliability of a product. It has a direct impact on enhancing product reliability, ensuring operational safety, and pushing technological boundaries. So, how is cryogenic testing done? What are the implications of the result of such testing? Read on to know more.

Cryogenic Shock Testing Principles

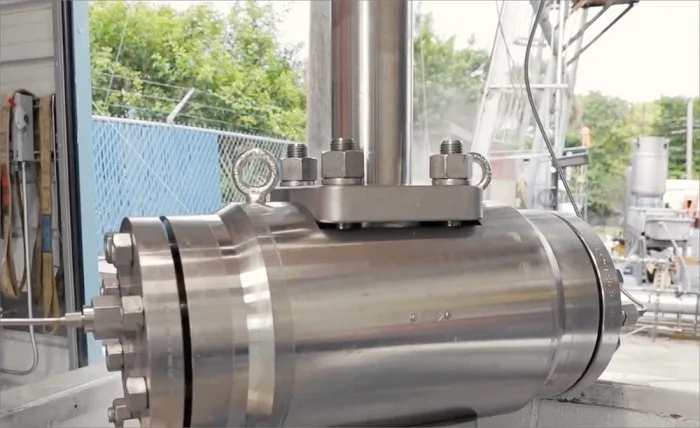

Cryogenic shock testing involves exposing small pressure vessels to extremely low temperatures, typically below -150 degrees Celsius, and subjecting them to sudden and intense pressure variations. Such conditions reflect the real-time influences that the vessels will be used in – as pressure transients to thermal cycling. Thus, the test will confirm if the vessel has the necessary characteristics to be used in extreme conditions and identify likely weaknesses in the vessel.

Implications of cryogenic shock testing

Cryogenic shock testing has emerged as an essential tool for evaluating the performance, reliability, and safety of small pressure vessels. The implications of cryogenic shock testing helps in the following industry-first practices-

- Enhancing Product Reliability-Small pressure vessels are subjected to harsh environments, ranging from space missions to deep-sea exploration. The ability to withstand extreme temperature variations and pressure differentials is crucial for ensuring their reliability and longevity. Cryogenic shock testing allows manufacturers to evaluate the performance of their vessels under extreme conditions, helping them identify design flaws, material limitations, and weak points that could lead to failures. By uncovering such vulnerabilities early in the development process, manufacturers can make necessary design improvements and optimize the vessel’s structural integrity, ultimately enhancing its reliability in demanding operational environments.

- Ensuring Operational Safety – Operational safety is of paramount importance when it comes to small pressure vessels. Failure or leakage of these vessels can have catastrophic consequences, risking lives, damaging equipment, and causing environmental hazards. Cryogenic shock testing serves as a critical tool for assessing the safety of these vessels. By subjecting them to extreme temperature and pressure fluctuations, potential weaknesses and failure modes can be identified and mitigated. This enables manufacturers to design vessels that are robust enough to withstand unexpected events, ensuring the highest level of operational safety.

- Pushing Technological Boundaries –Cryogenic shock testing not only helps ensure the safety and reliability of small pressure vessels but also drives technological advancements in materials, design, and manufacturing processes. The insights gained from this testing method enable engineers and researchers to push the boundaries of innovation. By understanding how different materials and structural configurations perform under extreme conditions, new materials can be developed, innovative design approaches can be explored, and manufacturing techniques can be refined. This continuous improvement in the field of small pressure vessels paves the way for advancements in other industries that rely on similar technologies.

- Regulatory Compliance and Industry Standards-Cryogenic shock testing plays a crucial role in meeting regulatory compliance and industry standards. Various international standards, such as those set by the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), outline testing requirements for pressure vessels. Cryogenic shock testing ensures that vessels meet these stringent criteria, allowing manufacturers to obtain necessary certifications and comply with safety regulations. Additionally, this testing method provides valuable data for validating and improving analytical models and simulation tools used in the design and assessment of pressure vessels.

Thus, by subjecting these vessels to extreme temperature changes and pressure differentials, manufacturers can identify weaknesses, improve designs, enhance product reliability, and ensure operational safety.

Conclusion

Thus, cryogenic shock testing methodology fosters continuous innovation and drives technological advancements in materials, design approaches, and manufacturing processes. As the demand for small pressure vessels continues to grow across industries, cryogenic shock testing will remain a critical element in ensuring the durability and performance of these vital components, ultimately pushing the boundaries of safety, reliability, and technological progress.