Infragas brings you cutting-edge technology with its catalytic infrared panels, a revolutionary solution that combines high-tech innovation with cost-effectiveness, rapid treatment speed, and space-saving benefits. These state-of-the-art infrared products redefine thermal processes in various industrial sectors, catering to diverse applications such as curing, pre-heating treatments, drying, and more.

The Science Behind Catalytic Infrared Panels

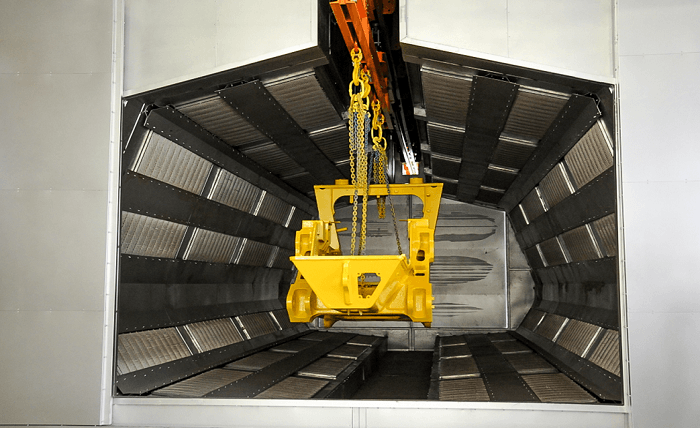

Infragas catalytic radiant heaters harness the power of infrared rays and operate with catalytic gas oxidation, all without the presence of an open flame. The advanced technology allows for a wide range of applications, making it a versatile and efficient solution for various industries. From liquid and powder coating curing to textile treatments, and even the wood and glass sectors, these panels provide unparalleled surface thermal processes.

A Diverse Range of Typologies to Suit Your Needs

Infragas catalytic infrared panels are available in two main typologies: INFRACAT and BOOSTERCAT heaters. These panels offer remarkable advantages that elevate them above traditional convection systems, and each typology serves distinct purposes to cater to your specific requirements.

Advantages of Infragas Panels

- High-Quality Results: The nearly absence of air movement ensures minimal contamination of the treated surface, providing a homogeneous, high-quality finishing without coating scaling, wrinkles, or bubbles, as commonly seen with liquid paint curing.

- Swift Start-Up Speed: The pre-heating phase takes only 10 minutes to reach the necessary temperature for the catalytic reaction, making it one of the fastest catalytic IR systems in the market.

- Space-Saving Compact Design: Infragas catalytic systems occupy only a third of the space compared to traditional convection systems, ensuring space efficiency without compromising performance.

- Quick and Efficient Treatments: The infrared radiation is directed solely onto the object, focusing on the item to be treated, resulting in high power density and significant energy and space savings.

- Temperature Modulation: By adjusting the gas flow rate, the radiant surface temperature can be modulated, ranging from 180°C (356°F) to 650°C (1202°F), ensuring optimal treatment conditions.

- Swift Cool Down: Infragas panels focus infrared medium/long waves directly on the treated item, enabling faster cooling down, minimizing the time and energy required.

- VOCs Abatement: The catalytic technology decomposes solvents and VOCs without burning, reducing atmospheric pollution and providing odor abatement in the working area.

- Safe Operation in Potentially Explosive Atmospheres: Infragas catalytic panels are FM and ATEX certified for use in potentially explosive atmospheres, thanks to the flameless combustion technology.

- Energy-Saving Efficiency: Gas, as the primary energy source, is more economical than electricity, and the targeted IR radiation results in quicker and cost-effective treatments.

Redefining Excellence in Catalytic Infrared Technology

Infragas stands at the forefront of the industry, setting new standards for excellence and innovation in catalytic infrared technology. As a company dedicated to delivering high-quality solutions, it has earned a reputation for being a trusted and reliable partner in the industrial sector. Here are the key reasons why Infragas is such a standout company.

Cutting-Edge Technology

This company takes pride in its continuous pursuit of advanced technology and research. Their panels are a testament to their commitment to providing state-of-the-art solutions that surpass traditional methods. By harnessing infrared rays and catalytic gas oxidation, Infragas offers unmatched efficiency and precision in a wide range of thermal processes.

Unparalleled Expertise

With years of experience in the industry, this company has accumulated invaluable expertise in designing and manufacturing catalytic infrared systems. Their team of experts includes skilled engineers, technicians, and researchers, all dedicated to developing products that cater to the evolving needs of various industrial sectors.

High-Quality Manufacturing

Infragas’ commitment to quality is evident in every aspect of their products. From sourcing top-grade materials to adhering to strict quality control measures, they ensure that each catalytic infrared panel meets the highest standards of performance and durability. The result is a reliable and long-lasting solution that stands the test of time.

Versatility and Customization

The company understands that each industry and application is unique. To cater to this diversity, they offer a diverse range of panels, including the INFRACAT and BOOSTERCAT typologies. This level of versatility allows customers to find the perfect solution tailored to their specific requirements.

Focus on Environmental Responsibility

Infragas is not only committed to delivering exceptional performance but also to minimizing its impact on the environment. Their catalytic technology ensures a reduction in VOC emissions, contributing to cleaner air and safer working conditions. As a result, catalytic infrared panels are ATEX and FM certified for use in potentially explosive atmospheres, providing a safe and eco-friendly heating solution.

Customer-Centric Approach

The company places customers at the heart of their operations. They take the time to understand each client’s unique needs, offering personalized solutions and excellent customer support. Their dedication to customer satisfaction has led to long-lasting partnerships and a loyal clientele base.

International Quality Standards

As a testament to their commitment to excellence, Infragas designs, manufactures, and tests its products according to the International Quality Standard ISO 9001. This dedication to meeting international standards ensures that customers receive products of the highest quality and reliability.

Continuous Innovation

This company never rests on its laurels. They actively invest in research and development to stay ahead of the curve, continuously improving their catalytic infrared technology and exploring new applications in different industries.

Global Reach

Infragas’ reach extends far beyond its home base. With a global presence, they serve clients from various corners of the world, providing top-tier solutions and expert support wherever they are needed.

This manufacturer has become synonymous with excellence, reliability, and cutting-edge technology in the field of infrared systems. Their dedication to innovation, customer satisfaction, and environmental responsibility sets them apart as a truly exceptional company that continues to shape the future of thermal processes in the industrial sector.

See the Difference for Yourself

Infragas catalytic infrared panels are the epitome of efficiency, precision, and reliability. Whether you require high-quality finishing, quick treatment times, or an eco-friendly solution, these panels are designed to exceed your expectations in various industrial applications. Discover the future of thermal processes with Infragas catalytic infrared panels, and revolutionize the way you approach heating, curing, and drying in your industrial processes.