This guide introduces the fundamentals of component assembly, which is an important process used in many industries, such as electronics and automotive. Here, besides the definition and the underlying principles of collecting, you’ll know more about the tools and equipment needed to use them effectively, the different applications in various industries, and the possibilities that are shaping its future, you can also learn how to choose the right raw materials to ensure your projects successfully reach their desired outcomes.

What is Component Assembly?

Component assembly usually refers to a process in software engineering where individual, pre-built components are assembled into a larger software system or application This approach is a broad concept called “component-based software engineering” (CBSE) of the section, which focuses on the design and development of recyclable software systems using reusable components.

Some key features of component assembly include modularity, reusability, interoperability, and standardization. In practice, component assembly involves selecting appropriate components and integrating them through their defined interfaces, usually with the help of middleware that helps manage communication and data exchange between components. This approach, whether in web development, large enterprise applications, or internally developed components, can be found in products.

Principles of Component Assembly

Principles of compilation are basic guidelines that help you to efficiently design, select and integrate software components to create robust and maintainable systems. General principles commonly followed in Component-Based Software Engineering (CBSE). Here are some of them:

- Encapsulation: Each component should contain its own functionality, exposing only the necessary interfaces, while hiding its internal functionality. This allows components to be understood and used based solely on their interface, without having to know the internal detail.

- Separation of concerns: A software application should be handled by separate components. This principle reduces complexity by dividing the application into manageable components, when each one will responsible for a specific function.

- Modularity: Components should be modular, which means they are designed as independent and interchangeable units. This modularity allows for easy maintenance and upgrades while parts can be changed or replaced without affecting other parts of the system.

- Reusability: Components should be designed with reusability in mind, so that they can be used to perform similar tasks in different applications. This not only accelerates the development process but also ensures consistency in product variety.

- Interoperability: Components should be able to work together seamlessly, despite being independently designed. To ensure compatibility with other components and systems, standard interfaces and protocols must be used to communicate.

- Scalability: The layout of the components should support scaling by allowing them to scale up to handle more critical loads or combining more instances of the product as needed.

- Compositionability: Ingredients must be designed in such a way that they can be easily combined with other materials. This requires intermediaries and communication systems that facilitate the integration of components into larger platforms.

- Manageability: Efficiency includes the ability to monitor, organize, manage and control components during runtime. This is important for maintaining a smooth operation and reliability of the system.

- Customization and Configuration: Components should be customizable and configurable so that they can fit different needs and requirements without changing the original code of the components.

These principles are important for the benefits of component assembly, such as reduced development time, increased software, lower maintenance costs and guide the development integration process, ensuring that the packaged system is more than just a collection of parts – it’s a union, a kind of well-functioning entity.

Tools and Equipment for Component Assembly

In a variety of industries, it is important to have the right tools and equipment to ensure efficiency and accuracy when assembling raw materials. This guide will identify the basic tools and equipment needed to successfully collect the contents.

- Automated Assembly Systems: Automated assembly systems are at the forefront of component assembly. They have both robotic arms and assembly lines, which are essential for high production volumes, and provide unmatched speed and power.

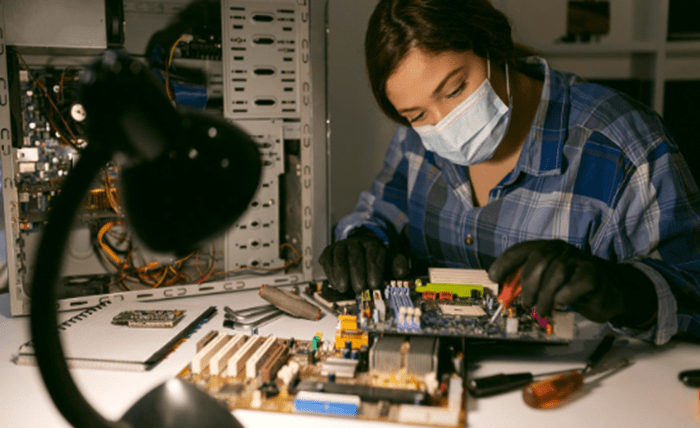

- Manual Assembly Tools: Manual tools are a must for smaller or more advanced component assembly jobs. Essential hand tools such as screwdrivers, tweezers and pliers are crucial for detailed assembly work, increasing accuracy and reducing the risk of damage.

- Soldering Equipment: Soldering iron and stations are required for electronic component assembly. Adjustable temperatures and different tip sizes should be provided to accommodate different components.

- Adhesive dispensing device: The dispensing device ensures uniform and consistent application of adhesives. Options range from simple hand delivery to sophisticated programmable devices.

- Inspection and Testing Equipment: Inspection and testing is necessary to ensure quality and efficiency. Instruments such as magnifying glasses, microscopes, multimeters and oscilloscopes help identify potential defects or deficiencies in the final product before being shipped.

- Equipment Packaging: After assembly and testing, mechanical packaging protects products during storage and transport. Vacuum sealers, blister packaging machines, and foam inserts are often used to ensure that components are securely packaged and not damaged.

Selecting appropriate tools and equipment for manufacturing processes has a profound effect on product quality and manufacturing efficiency. Invest in intelligence to maintain a competitive edge in manufacturing and increase operational efficiency.

Applications of Component Assembly

Component assembly is a key process in many industries, allowing complex systems to be built from individual parts. Below, let’s explore some of the key areas where component assembly is important.

- Electronics and Consumer Devices: In the electronics industry, component assembly is essential for the manufacture of devices such as smartphones, computers and televisions. This process involves precise placement and soldering of components such as capacitors, resistors and integrated circuits on printed circuit boards.

- Car manufacturing: The auto industry relies heavily on assembly lines to produce cars. It involves an integrated engine, transmission and electronic system that requires extreme precision to ensure safety and performance.

- Aerospace and Aircraft: Aerospace uses assembled materials to manufacture aircraft and spacecraft in strict adherence to safety and performance standards. It involves a wide range of hydraulic systems, engines and aircraft equipment, of which critical to aviation operations and safety.

- Medical Devices: The medical industry benefits greatly from consolidation in the manufacture of devices such as pacemakers, cameras and surgical instruments. Collection methods must meet high standards of accuracy and purity to ensure patient safety.

- Telecommunications: Component assembly plays an important role in telecommunications, facilitating the construction of routers, switches, base stations and other infrastructure that enable global communications.

- Industrial Machinery: This activity involves the assembly of raw materials into machines used in manufacturing and other industrial industries. This includes conveyor belts, robotic arms and manufacturing processes that automate and streamline manufacturing processes.

Its applications are critical to the development and efficiency of modern technology, encompassing everything from everyday objects to the sophisticated industrial devices that allow us to enjoy and transport these complex systems we rely on it in our daily lives.

Future Trends in Component Assembly

As technology continues to evolve, there are set to be significant changes in parts assembly. Here’s an overview of some of the key future trends expected to shape the component assembly landscape:

- Increased automation and robotics: Component assembly automation is expected to be increasing, with more sophisticated robotics and AI systems that will take over jobs requiring greater accuracy and repetition These changes are not necessarily going to improve efficiency only reduce the chances of human error, which leads to superior results.

- Integration of IoT and smart manufacturing: The Internet of Things (IoT) plays a key role in component assembly by enabling intelligent manufacturing processes. Sensors and smart devices will collect and analyze data in real-time, enabling predictive fixes, supply chain streamlining, and quality control.

- Adoption of 3D Printing: 3D printing technology is poised to revolutionize component assembly, especially for complex parts and customized products. This technology reduces waste, reduces manufacturing costs, and accelerates assembly by printing materials directly from digital files.

- Advanced Materials: The development and use of advanced materials such as high-performance composites and polymers will affect component assembly processes. These materials offer excellent properties, including strength, heat resistance, and lightweight, opening up new possibilities in industries including aerospace and automotive.

- Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies are expected to become important tools in component assembly lines. Engineers can be provided with real-time guidance and visual cues, improving accuracy and reducing assembly time. This will be especially useful in the complex assemblies found in the aerospace industry.

- Sustainable Manufacturing Practices: Sustainability becomes more important in component assembly. Manufacturers focus on energy efficiency, reducing waste, and reducing their carbon footprint by using environmentally friendly materials. This trend is driven by both regulatory pressures and a shift in consumer preferences towards sustainable products.

The future of collectibles looks like a sharp, clear push towards smarter, more efficient, more sustainable manufacturing. By embracing these factors, companies can improve their production processes and adapt to the changing demands of the global market.

Choose a Suitable Component Assembly Service

Choosing the right component assembly service is essential to achieve high performance results, efficiency and reliability. When considering potential partners, consider Fisher Asia, a leading Metal Manufacturing Company in Vietnam, which is recognized as the number-one solution in the products industry.

With high-quality materials and meticulous attention to detail, Fisher Asia offers comprehensive services covering everything from manufacturing to final assembly and packaging. Fisher Asia is not just about assembling parts; they offer an all-encompassing service including metal printing parts manufacturing, in-depth drawing, molding and complete assembly.

As a prominent player in Component Assembly Services in Vietnam, their business is enhanced by advanced tooling solutions and internal processes is a robust quality control system that helps minimize potential defects, even before mass production begins.

Fisher Asia’s comprehensive approach ensures that every aspect of the assembly process is managed to the highest standards, making them a strong candidate for anyone looking to improve their manufacturing and assembly process.

Wrapping Up

Component assembly is important in various industries, especially with the improvement of advances in technology and practices. This guide outlines its principles, tools, applications, some future developments. Also, it is critical to identify the importance of choosing the right service like Fisher Asia for quality and efficiency, which has a great impact on the success of your business.